Our Services

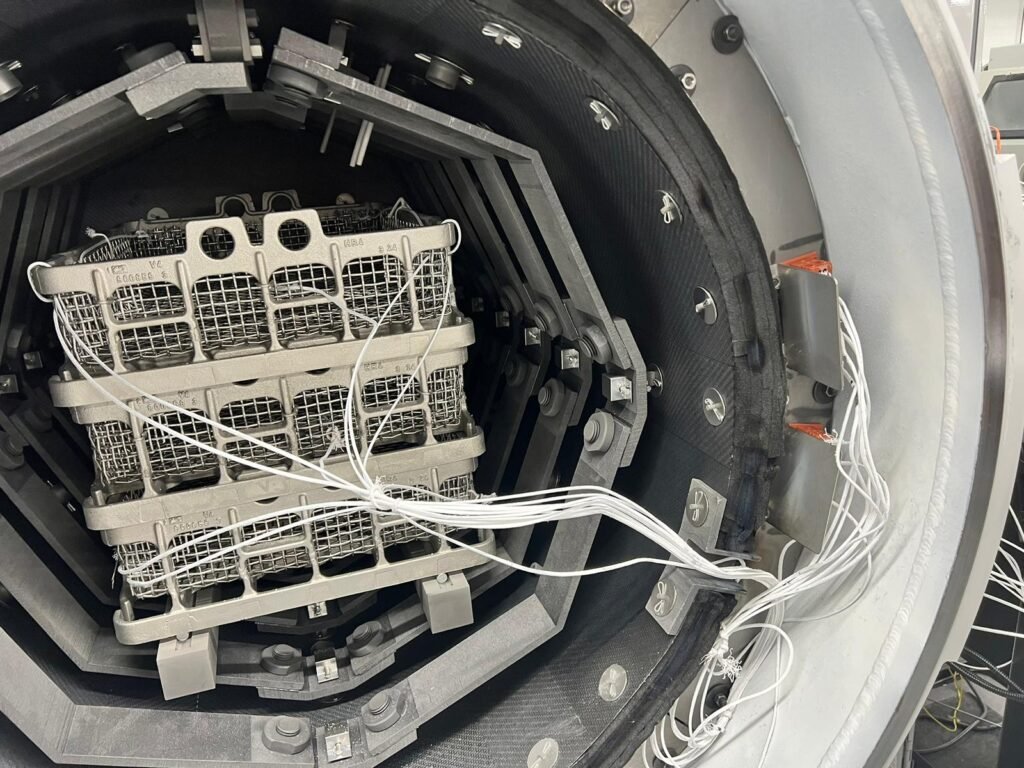

pyrometry Calibration & Testing

TUS Pyro’s highly skilled team is fully capable of performing in-depth root-cause analyses for any test failures, offering practical solutions or recommendations to resolve issues and prevent future occurrences.

Temperature Uniformity Survey

System accuracy testing

Instrumental Calibration

heat treatment training

On Site AND Customized Training Programs: Pyrometry (Basic and Advanced), Heat Treat Qualification for Operators, Planners, and Owners. Root Cause/Corrective Action. Hardness and Conductivity

nadcap consulting / compliance

We provide expert guidance to prepare and streamline your operations for NADCAP accreditation and heat treatment processes.

Why choose us?

With a team of NADCAP and ISO/AS9100 Lead Auditors who each bring over 25 years of specialized experience, TUS -Pyro combines deep technical knowledge with a comprehensive understanding of Aerospace standards and Heat-treating processes. Our team of professionals is equipped with in-depth expertise in internal auditing, training, calibration and pyrometry, including SAT (System Accuracy Test), TUS (Temperature Uniformity Survey), and instrument calibration testing services.

At TUS-Pyro, we’re dedicated to providing tailored consulting solutions that empower clients to operate with the highest levels of quality, consistency, and compliance, making us the partner of choice for Aerospace and manufacturing industries aiming to achieve and maintain NADCAP accreditation.

Choose TUS-Pyro as your trusted partner in assurance, quality, and continuous improvement.

Frequently Asked Questions

We look forward to hearing from you!